Alumni Step Up To Help Protect Workers on COVID-19 Front Lines

Two University of Texas at Dallas alumni have designed and manufactured a valve attachment that can convert a snorkel mask into safety gear for health care workers in the event of a shortage of personal protective equipment during the COVID-19 pandemic.

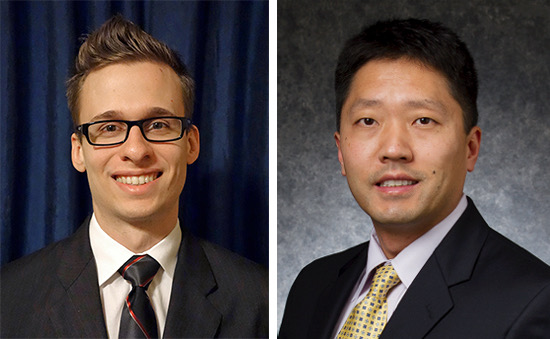

James Griffin BS’18, CEO and founder of the health care software company Invene, worked with Plano, Texas, anesthesiologist Dr. Peter Baek MS’15 to create the adapter that connects a hospital-grade bacterial and antiviral filter to a full-face snorkel mask. The adapter can be sanitized to use again with a new filter. Griffin, who earned his bachelor’s degree in computer science from the Erik Jonsson School of Engineering and Computer Science, and Baek are distributing the attachment for free. The masks have to be purchased separately. Similar efforts are being done across the country.

The pair partnered with the University’s UTDesign® Studio and Emerson Automation Solutions in McKinney to 3D-print the attachment at cost. Each part costs less than $10 to manufacture.

“Basically, we added a valve to a scuba mask. We’re using filters already proven to stop viruses. The resulting mask actually replicates the functionality of an N95 mask. It’s free – we just want to help doctors.”

James Griffin BS’18

After reading about similar solutions used by Italian physicians, Baek, who earned a master’s degree in healthcare leadership and management from the Naveen Jindal School of Management, contacted Griffin. The two had worked together through the University’s Venture Development Center, a business incubator that helped Griffin launch his company. Baek has experience mobilizing medical equipment under challenging circumstances. In 2005 he served as medical director of an Air Force expeditionary hospital at Baghdad International Airport.

Griffin, who received an OZY Genius Award in 2018, said he drew upon what he learned about entrepreneurship as a student at UT Dallas to rapidly develop, manufacture and distribute the valve.

The valve fits a DIVELUX full-face snorkel mask that Baek found easily available online; it may not work with other models, he said. Before they got to work, they made sure that the online retailer that sold Baek’s mask had a large supply. After several design changes, Baek and Griffin had a working prototype. The final attachment passed qualitative testing similar to the fit-testing done with an N95 mask.

Baek explained that many hospitals are asking health care providers to conserve N95 masks by using one per day due to the COVID-19 pandemic instead of one per surgery as they would under normal circumstances. In the hardest-hit U.S. cities, health care workers are limited to using one mask per week. Baek plans to use his adapted mask as a last resort.

“I started looking around to see if there are other ways that we as health care professionals can protect ourselves,” Baek said. “I contacted James and said I needed to 3D-print an idea as proof of concept. Let’s see what we can do and work together.”

The duo plans to continue manufacturing the adapters. They’ve received more than 200 requests, and the number increases each day. Baek and Griffin created a GoFundMe page to raise money for the materials for the adapters.

Media Spotlight: COVID-19 Response

Posts

You May Also Like